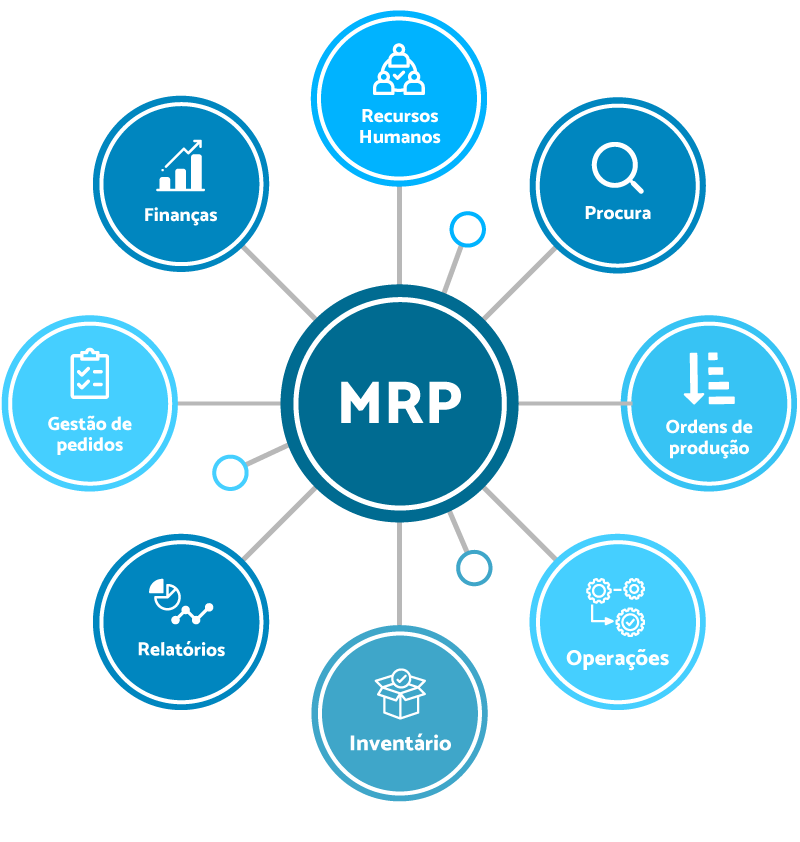

In today’s fast-paced business environment, leveraging manufacturing resource planning (MRP) software can significantly streamline operations and enhance efficiency. This sophisticated tool facilitates inventory management and process consolidation, ultimately accelerating production processes and simplifying workflow management.

The functionality of MRP software revolves around a robust set of algorithms designed to coordinate production activities seamlessly. By automating tasks such as supply ordering, order sorting, and inventory tracking, MRP software empowers businesses to maintain optimal inventory levels while minimizing overhead costs. Moreover, it enables quick identification and resolution of manufacturing bottlenecks, cost inefficiencies, and performance evaluation within the production facility.

How MRP Software Operates

MRP software enables users to craft comprehensive production plans aligning materials, components, and resources with output requirements. This involves factoring in variables such as inventory availability, production costs, capacity utilization, lead times, and associated processes. By integrating these elements, the software ensures precise production scheduling and execution, leading to timely delivery of high-quality products.

Central to its operation is a robust database housing critical information on production schedules, costs, inventory status, and manufacturing processes. Leveraging predictive analytics, MRP software identifies areas ripe for improvement, empowering users to enhance cost-effectiveness, quality, and operational efficiency proactively.

Benefits of MRP Software Integration

The adoption of MRP software yields a myriad of benefits, notably enhancing production planning, resource allocation, and cost management.

Improved production planning enables businesses to optimize resource utilization, boost output, and trim costs. This results in heightened operational effectiveness, enhanced accuracy, and expedited production cycles.

Efficient resource allocation is another key advantage facilitated by MRP software. By aiding in downtime planning, raw material procurement, and inventory optimization, the software minimizes disruptions and ensures an accurate inventory profile, thereby reducing expenses associated with downtime and inventory management.

Furthermore, MRP software empowers businesses to exercise better control over costs by factoring in material, labor, and resource expenses. This meticulous cost analysis ensures that products or services are manufactured at the most competitive price point, bolstering profitability.

Conclusion

In conclusion, MRP software serves as a pivotal tool in streamlining business operations, enhancing efficiency, and reducing costs. As organizations increasingly rely on technology, the adoption of MRP software is becoming ubiquitous. To maximize its benefits, it is imperative for businesses to evaluate their existing processes and explore various MRP software options before making a decision. By selecting the right MRP solution tailored to their specific needs, businesses can optimize operations, boost efficiency, and drive sustainable growth.